|

|

|

JUKEBOXES

UNLIMITED.com®

Established

1971

Los Angeles,

CA 91394

1-818-366-9400

Our

jukeboxes have been professionally rebuilt/restored

and include a full one year parts warranty.

We ship worldwide.

|

How

Jukeboxes Unlimited ® Rebuilds Jukeboxes

When

Jukeboxes Unlimited ® rebuilds a jukebox, there is little we don't

do. But, it takes years

of experience to produce great sounding and great working jukeboxes.

Here's what we do:

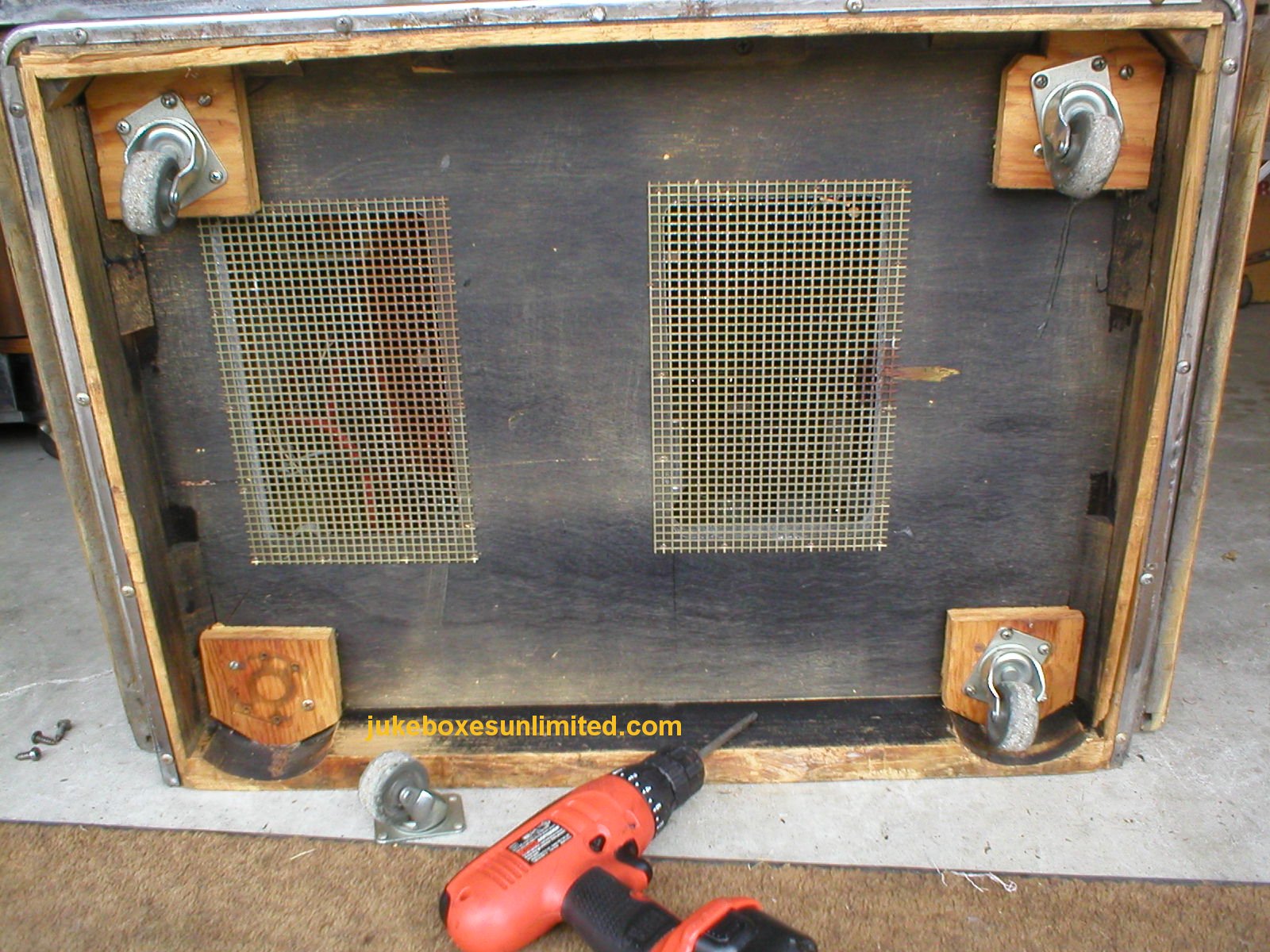

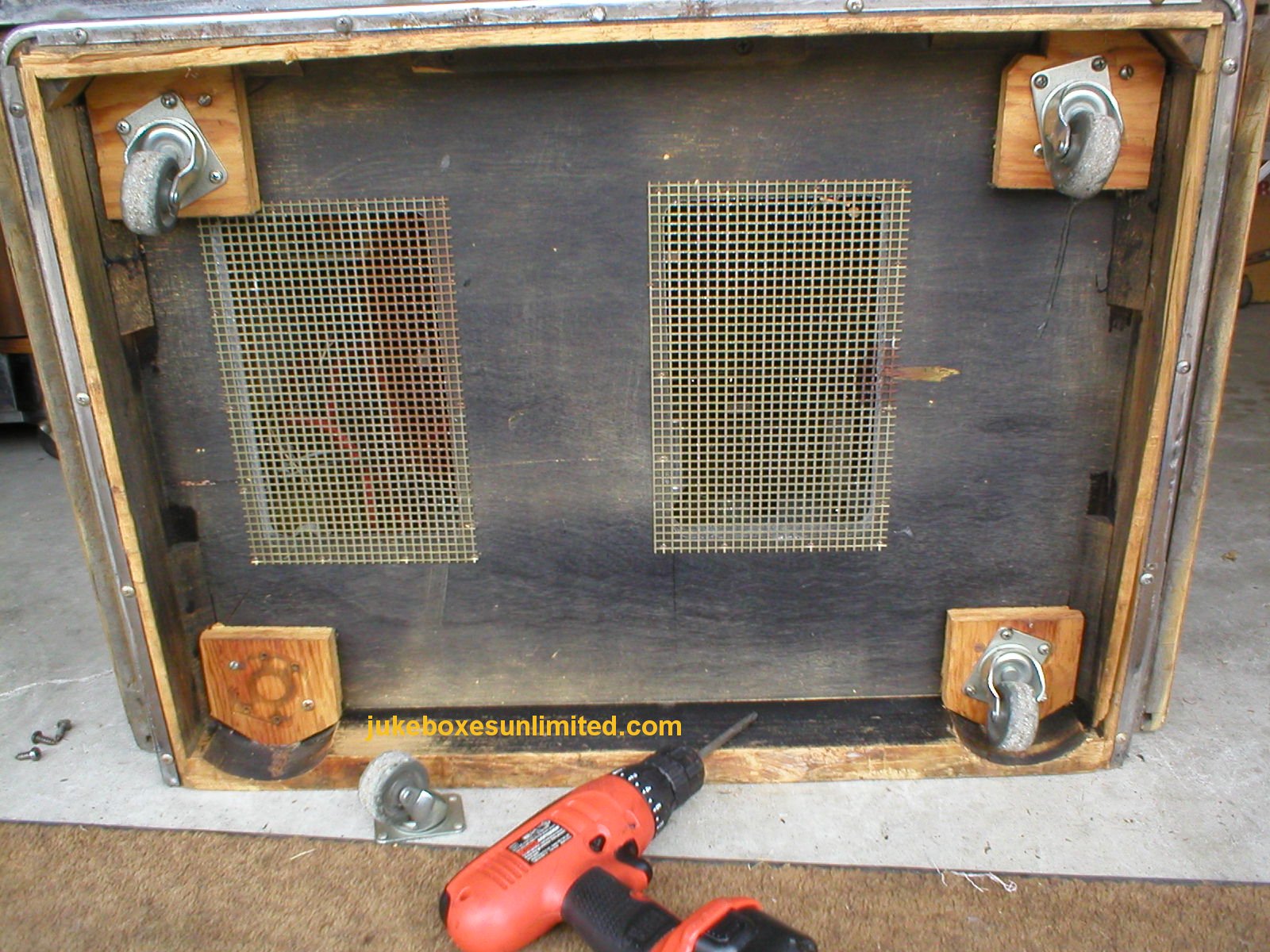

Wheels

Most jukeboxes have steel casters that will mar floors.

Replacement rubber casters on a 1956

Seeburg VL-200.

When

it can be done, we install rubber wheels.

New casters on a 1958

Seeburg 161.

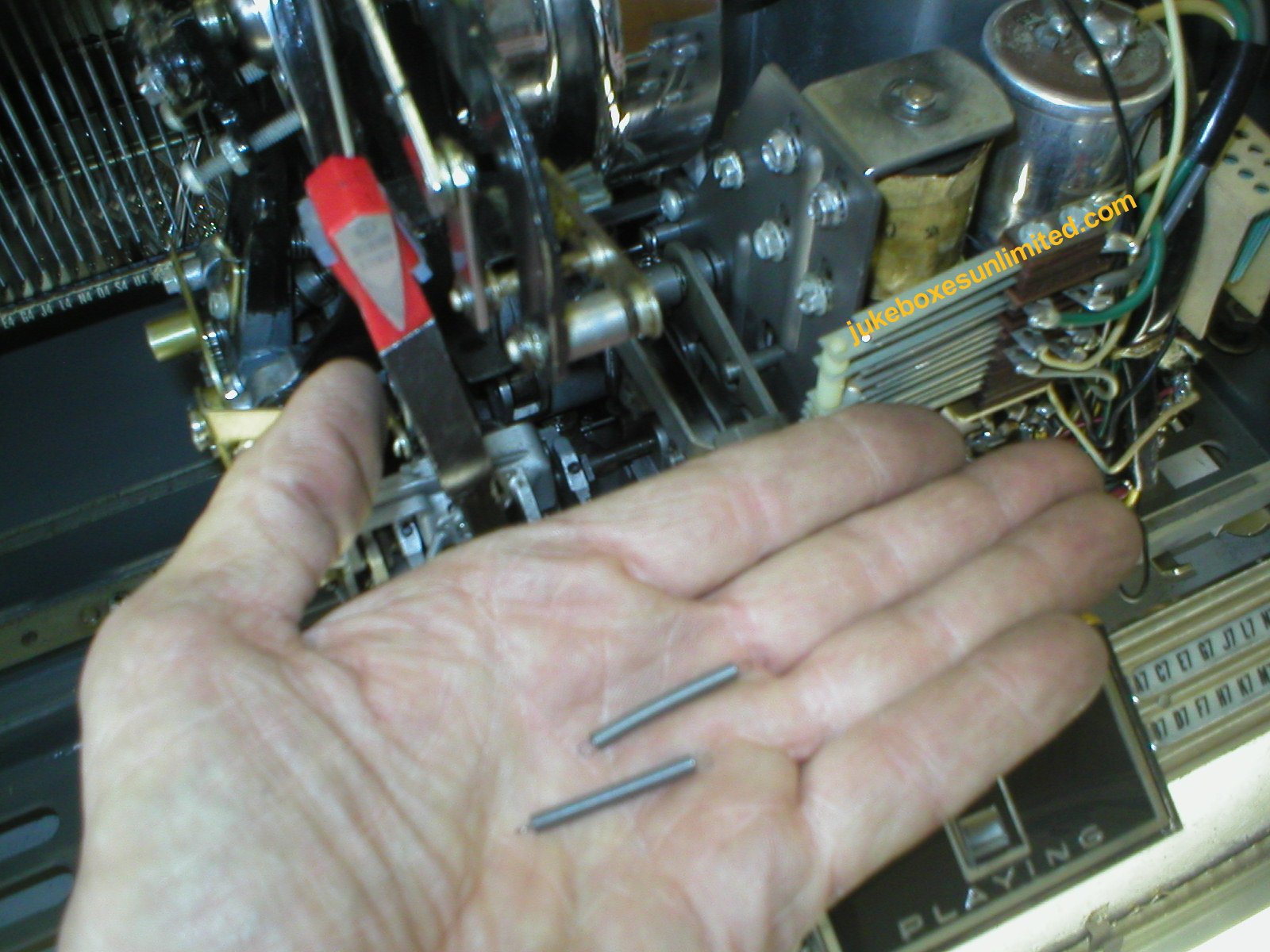

Needles

There are good ones and bad ones. It takes research to know the

correct ones.

Some needles can be louder than others. Using the wrong mil

(thickness) needle and it can

destroy your records.

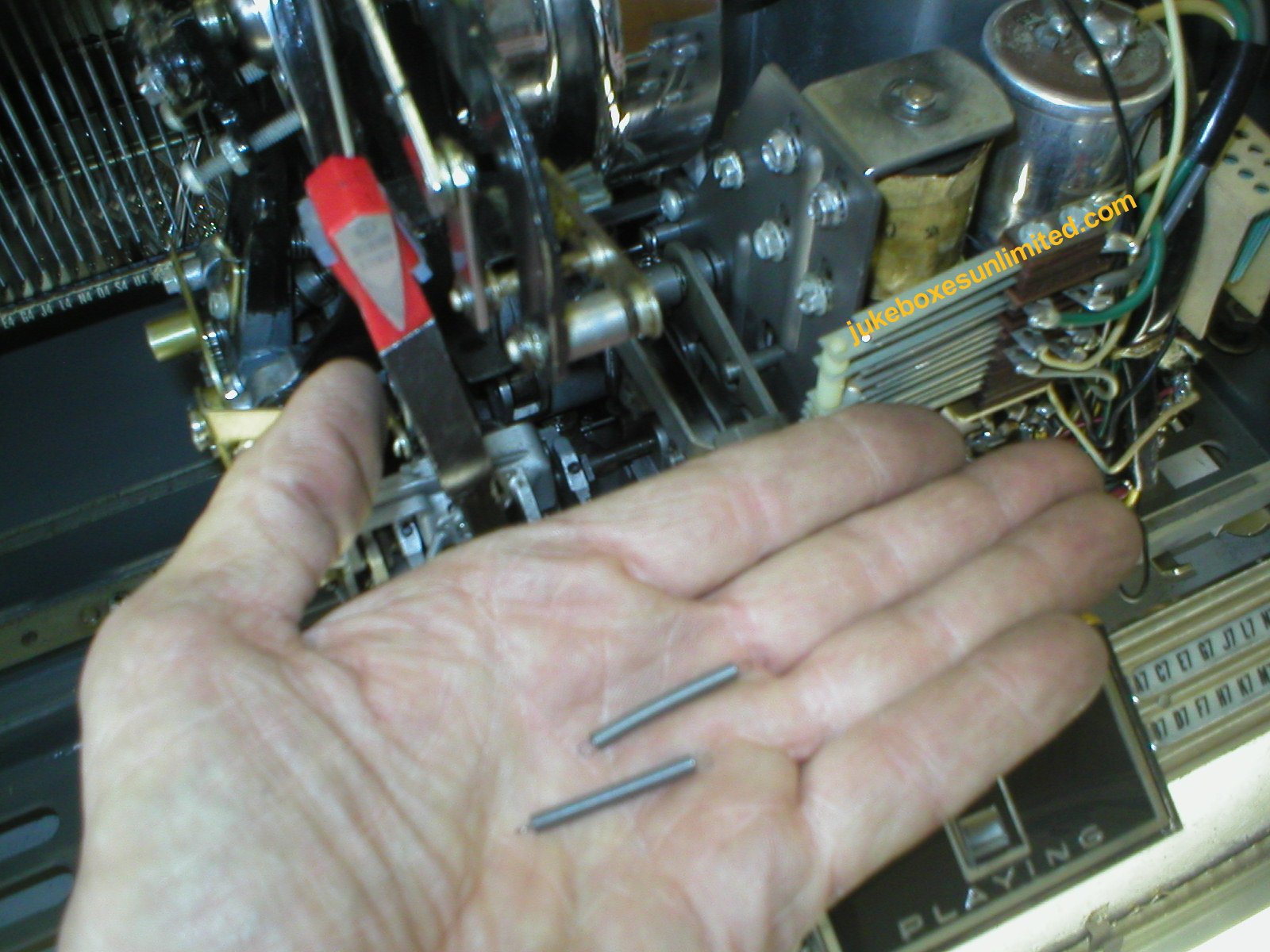

Tone-arm

pressure

You need the right equipment to be able to set the tone arm

pressure,

you can't just guess or tape a quarter to it. The wrong tone arm

pressure will track heavy

and eat up your valuable records.

Tonearm springs for a

Seeburg mechanism.

Speakers

You have to know what you're doing when replacing speakers that are

bad.

You can't just replace it with a new one because speakers are tuned to

their cabinet.

For example, Seeburgs have odd impedances, 4, 6, 12 ohms.

Installing an 8 ohms speaker

in a Seeburg will drastically reduce the sound output. Most

early jukeboxes have very

efficient sound systems that are designed for low output

speakers.

Grill

Cloth

Most folks don’t

know the difference between fabrics from a fabric store and grill

cloth. They can look identical, but real grill cloth lets the

air flow through easily whereas plain fabric restricts it. When

sound is produced through a speaker, the cone of the speaker moves in

and out moving air. This quick moving air can make plain fabric

oscillate or thump against the grill. This thumping distorts the

bass notes and the sound comes out mushy.

A

while back we purchased cloth from a well known jukebox supplier for a

Seeburg “R” that turned out to be just shiny cloth. We had to

inform him; he didn’t know the difference. What was scary is

that he told us he’d been selling it for years and we were the first

and only ones who caught it.

Cabinets

We clean the machine inside and out.

Lubrication

We lube and adjust all aspects of each unit with the proper

lubricants.

There isn't just one lubricant that can cover it all. We've

learned which ones work best

for each specific application. We NEVER use WD-40.

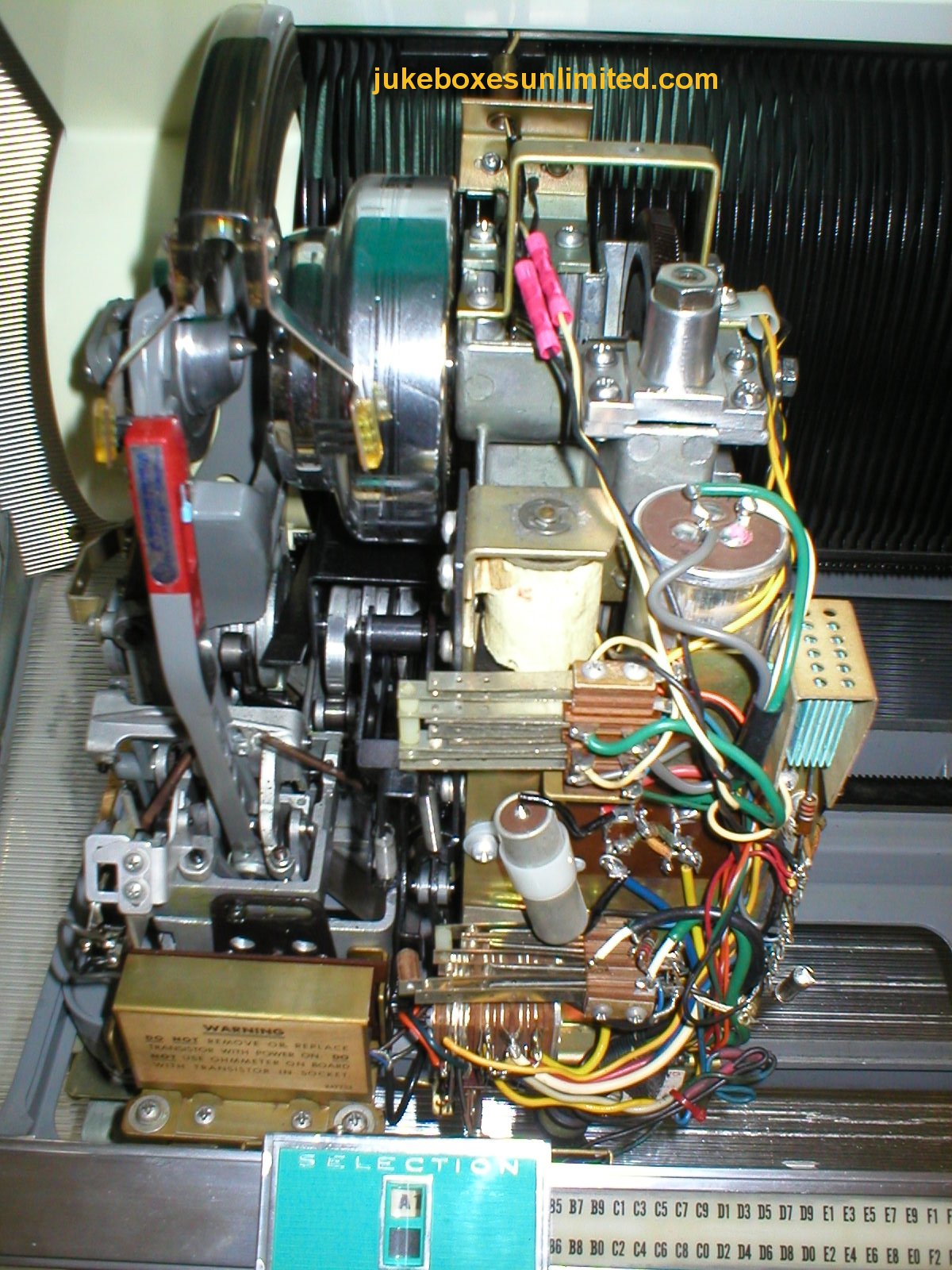

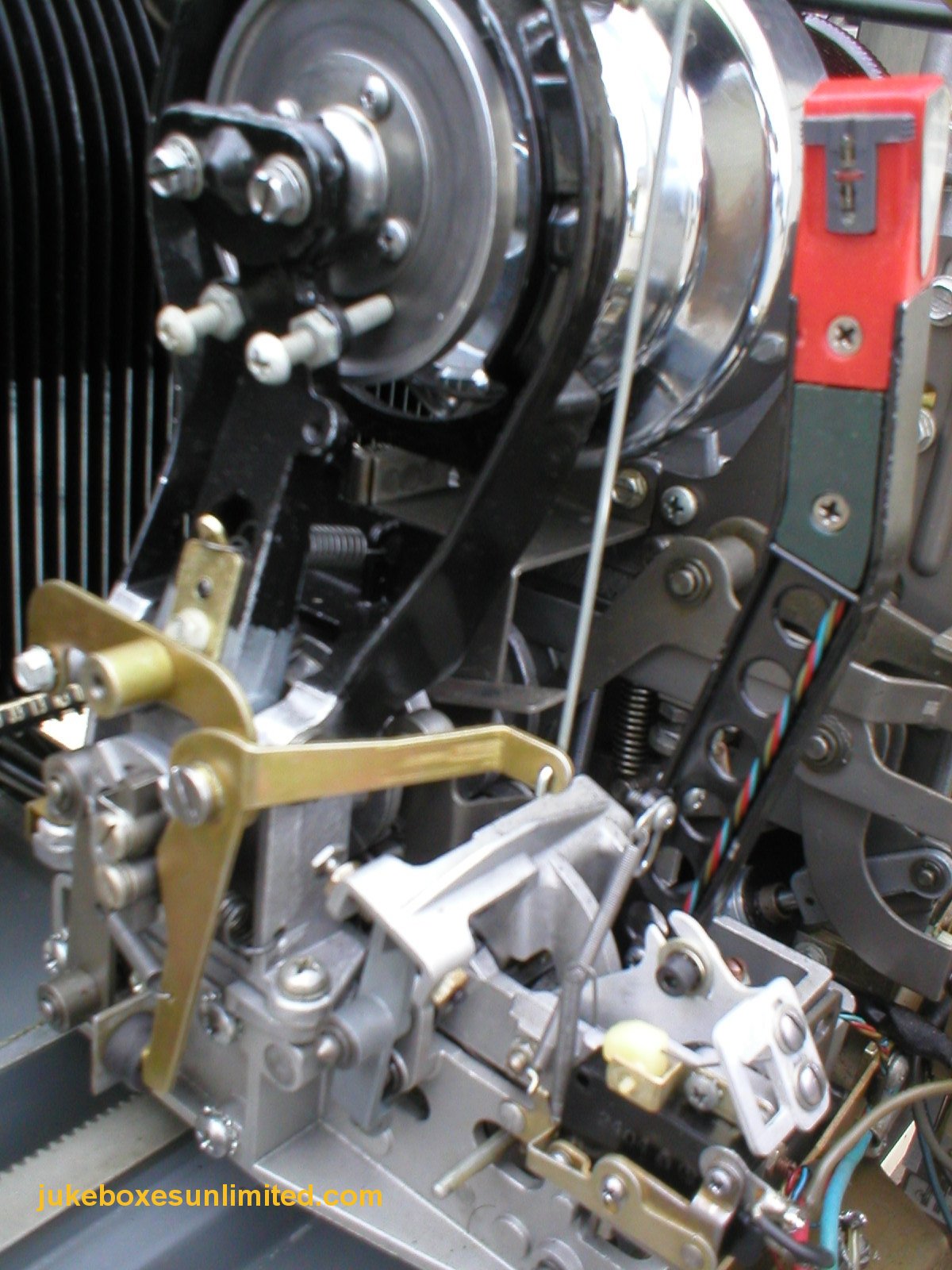

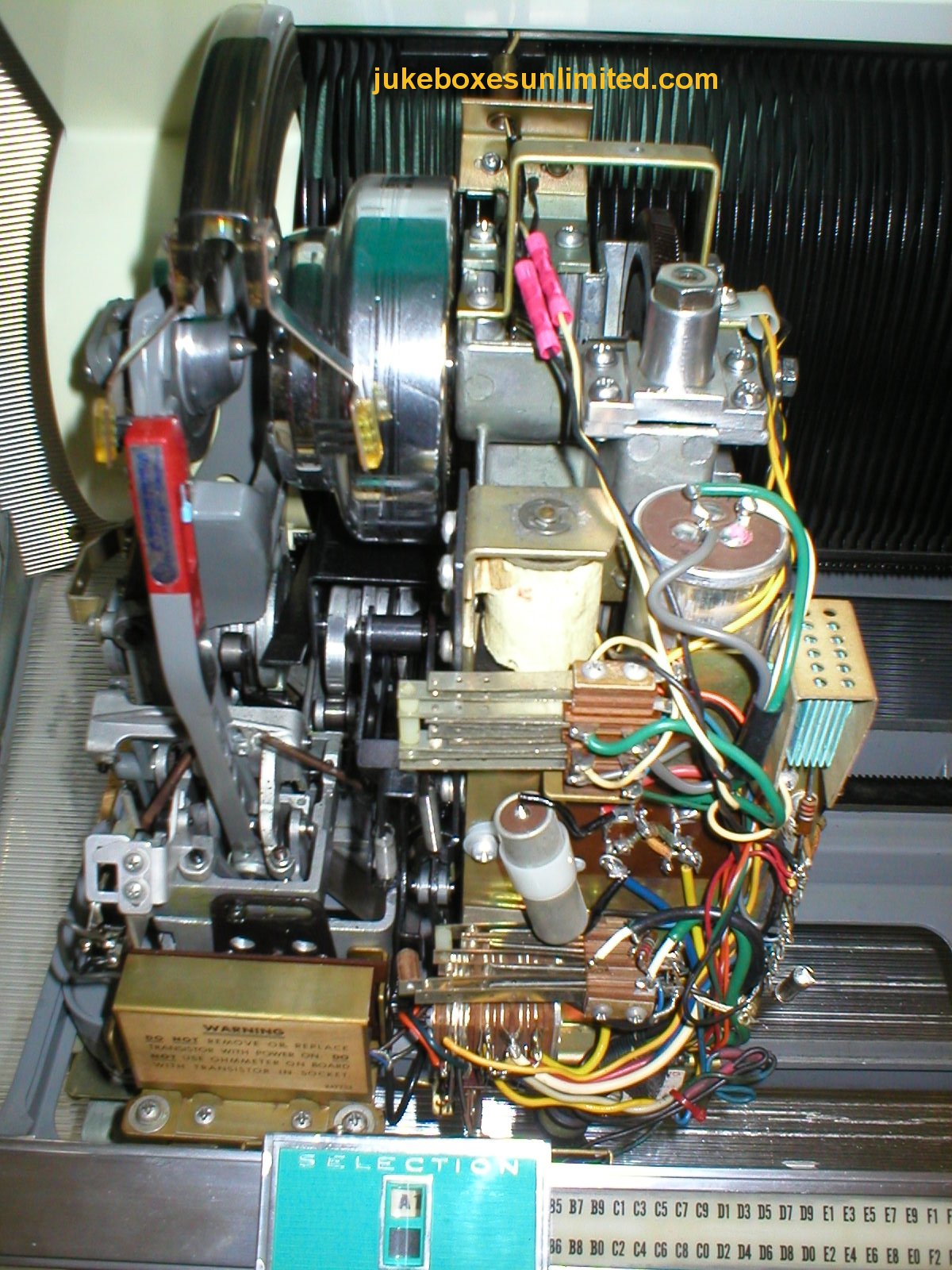

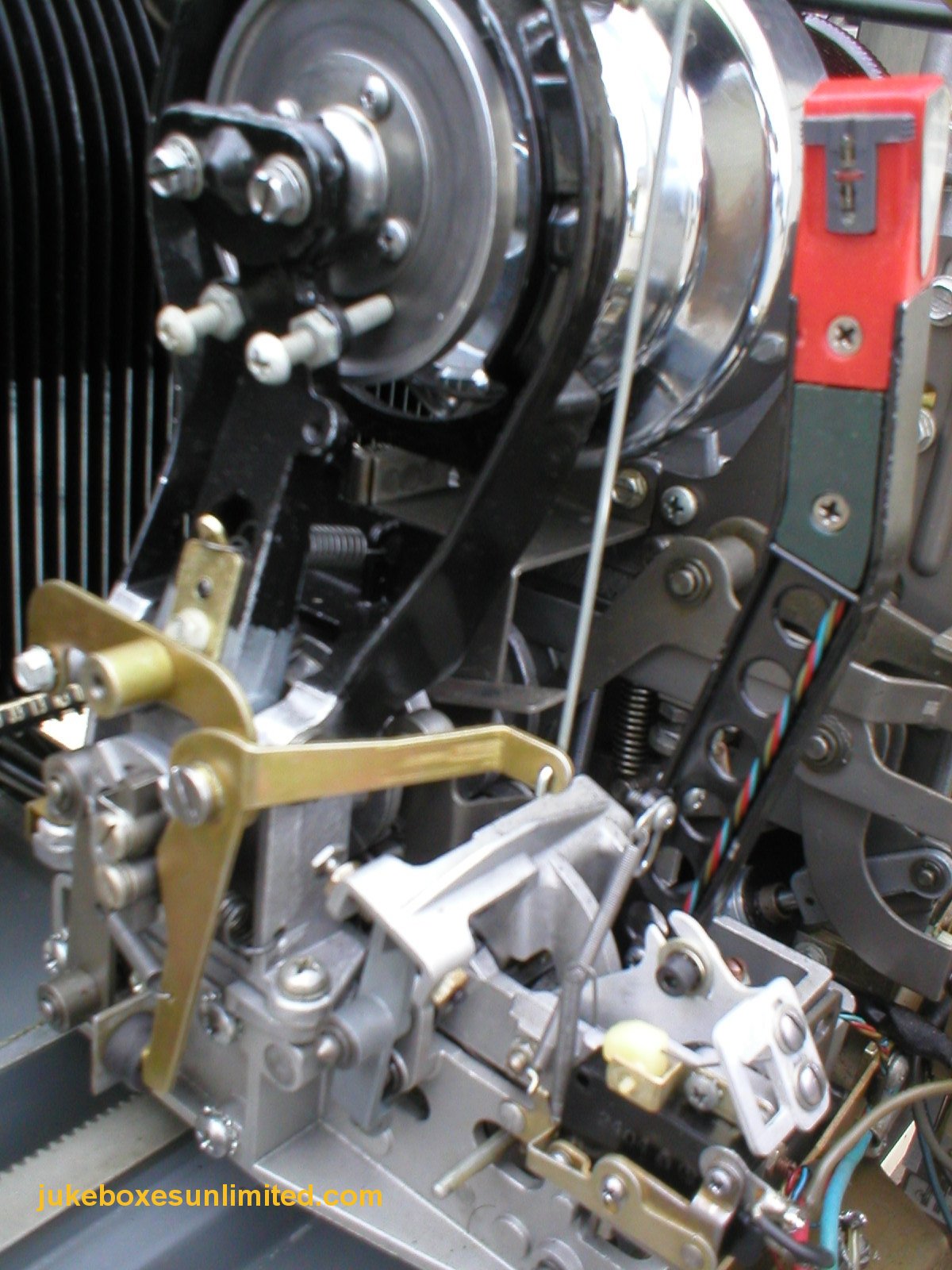

Mechanisms

Cleaning, lubricating and adjusting mechanisms is a very critical

aspect

of properly rebuilding a jukebox especially with Seeburgs.

Before

After

Mechanisms of a Seeburg "C" before and a Seeburg

"L" after cleaning.

_________________________________________________________________________________________

Before

After

Mechanisms of a Seeburg "C" before and a Seeburg

"222" after cleaning.

Fine

Tuning

After everything is finished we run each jukebox for days, at times

cranking them all the way up.

Fun

A detailed jukebox from Jukeboxes Unlimited ® is ready to go home

with you now.

|